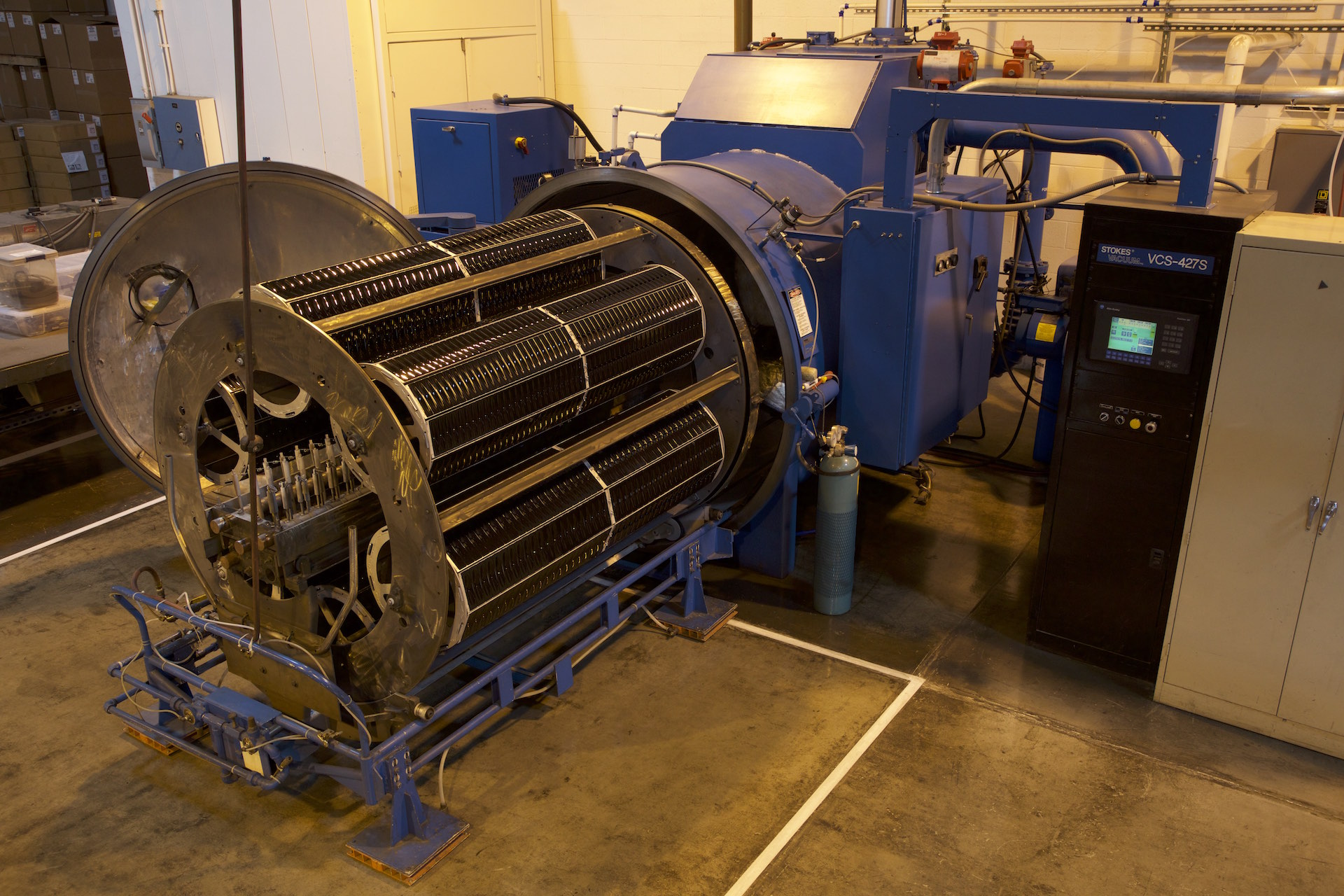

VACUUM METALLIZATION (PVD)

Vacuum Metallizing or Physical Vapor Deposition (PVD) is a thin film deposition process in which a material (metal, alloy, compound) is evaporated onto a substrate in a vacuum. At PF Technologies the vacuum metallizing process is used for decorative metallic finishes, EMI/RFI Shielding, and Reflective coatings on plastic, glass, and metal substrates.

- Decorative Metallic Finishes – PVD – The PF Technologies process provides a wide range of metallic finishes including matte/brushed finish, reflective chrome finish, and reflective color finishes. Utilizing our robotic paint capabilities (base coat, top coat) in combination with our vacuum metalizing capabilities provides multiple decorative choices for your needs.

- EMI/RFI Shielding – PVD – PF Technologies has a custom designed Stokes Vacuum System. It features a PLC controlled three (3) fire PVD system capable of depositing up to 3 microns of metal. Materials such as aluminum, copper, stainless steel and nickel chrome can be deposited individually or combined. Our PVD capabilities are another processing option PF Technologies provides to meet your stringent EMI/RFI testing requirements.

- Reflective Coatings – PVD – PF Technologies deposits a fine coating of aluminum on a polished plastic, glass, or metal surface providing reflectivity up to 94%. Aluminum is an excellent reflector, collimating and refocusing both visible, ultra violet and infrared light. Reflective coatings can be deposited on 1st or 2nd surface depending upon customer specifications. Mirrors can be created on acrylic and glass, both 1st and 2nd surface. Other evaporation materials used to create reflective parts have been Nickel/Chromium, Stainless Steel, and Indium.

Comprehensive Services

Vacuum metallizing, or Physical Vapor Deposition (PVD), services from PF Technologies are a true distinguishing feature of our company.

- Multi – layering capability: We can deposit up to 3 materials without breaking vacuum.

- Accurate, repeatable processing: Our state-of-the-art PLC processing controls perform at repeatable, accurate cycling parameters.

- More choices: Decorative cosmetic coatings services, EMI/RFI shielding using conductive coatings, die cut gasketing.

Tell us how PF Technologies can help you with your vacuum metallization coating needs.

Best Overall Job Value

At PF Technologies, our high yield rates and automated production efficiencies leave foreign competitors in a quandary, wondering how it’s done. It’s quite simple, really. We use the latest production practices in a 40,000-square foot facility designed for production. We hire the best possible workers and treat them right. That’s why our average production worker has been with us more than 12 years. Try finding that in an overseas center.

You can count on these results when working with PF Technologies:

- High yield rates handled with speed and efficiency.

- Flexible options – We can design, tool, prototype, process and package.

- Fast turnaround from our multiple shift capacity production center.

Learn more about how PF Technologies in Arizona can help you with vacuum metallization services. Complete our privacy assured online contact form or call us at (602) 243-6293.